Nowadays, the most common way to obtain very fine particles from suspensions is a combination of spray drying and a subsequent grinding process. This grinding step is necessary because the final product is agglomerated. In contrast to this, the media slurry dryer generates an end product with particles of the same size as in the original suspension in one step.

Mercedes Nanu

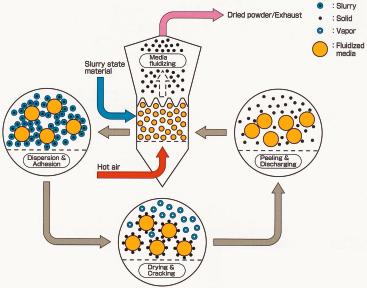

The slurry is pumped from a vessel into a fluidised bed of inert media beads inside the drying tower. It is there that the particles in the slurry are dispersed, adhered and dried on the beads before being carried out by the gas stream. Hot gas is used for drying. If the gas is air, the air heating and drying process takes place in the following steps:

The air is drawn in through a suction fan from the ambient atmosphere, pre-filtered, heated and finally blown into the dryer. The hot air moves the media beads, forming a fluid bed with a high heat transfer. The moisture in the slurry is evaporated after a short time due to the very large surface area of the beads, so that only solid material remains on their surface. The gradually reduced adhesion between the product and the media beads and the bead movement together cause the small product particles to be peeled from the beads. The end product, a very fine powder, is subsequently entrained by the exhaust air and collected in the cyclone or bag filter. Hazardous slurry materials, such as flammable solvents or materials that are liable to cause dust explosions, can be safely processed in the closed system variant of the media slurry dryer using inert gas.

Compact design

The very large surface area of the media beads and the fluid bed movement result in an extremely efficient heat and mass exchange between the phases and thus very quick and effective drying. Various tests with the media slurry dryer have shown a heat capacity coefficient greater than 8500 kJ/m³Kh. Against this background, a media slurry dryer is up to 20 times smaller in size than a spray dryer with the same throughput.

Another major advantage of the media slurry dryer compared to spray dryers derives from its ability to dry viscous slurries as well (up to 10 Pas). This is due to the fact that it dispenses with a spray unit, which could obstruct during the process. The slurry is dispersed only by means of the media beads from the fluid bed.

The media slurry dryer can be supplied in various sizes: equipment with an evaporation capacity of between 2 and 1450 kgwater/h and a fluid bed surface ranging from a few square centimetres to several square meters is in use.

cpp 428

Share: