Emerson Process Management has announced the latest release of the Rosemount 3420 Fieldbus Interface Module (FIM). Designed for users in facilities without fieldbus I/O, the Rosemount FIM enables installation of Foundation Fieldbus devices with any host system. This capability extends the proven benefits of PlantWeb digital architecture to existing plants.

The latest release of the Rosemount 3420 provides access to predictive diagnostic information from the fieldbus devices, enabling asset management and performance optimisation within the AMS Suite: Intelligent Device Manager software. For example, users are able to add powerful AMS SNAP-ON applications like AMS ValveLink for continuous monitoring of digital valve health, allowing predictive maintenance and avoidance of abnormal situations. The FIM also enables control in the field using peer-to-peer communications between fieldbus devices.

Process monitoring, such as temperature and machinery monitoring and many smaller discrete areas of process automation in the plant, can be improved when automated with fieldbus devices through the Rosemount 3420; they include flare automation, remote loading/unloading docks and metering stations.

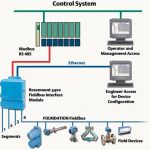

The Rosemount 3420 FIM uses web server technology to simplify commissioning, configuration and maintenance tasks. The scaleable architecture provides a maximum of four separate Foundation Fieldbus segments, including power conditioners. Control can be shifted into the field, enabling tighter action and higher production yields. External communications with any basic process control system are achieved using Modbus RTU (RS485), Modbus TCP/IP (Ethernet), HSE and OPC interfaces. The Rosemount 3420 is also compatible with commercially available wireless solutions.

Project at BP Hull

BP has used the Rosemount 3420 Fieldbus Interface Module to realise the benefits of adding fieldbus technology to its existing plant and traditional DCS control system at its Hull chemicals plant.

When BP initiated the project – requiring temperature monitoring of over 200 points on its ethyl acetate process reactors – in a Zone 2 hazardous area, the attractions of the reduced cabling and lower number of interface modules needed with a fieldbus solution were considerable. The Emerson proposal for monitoring 200 points or more using just two Foundation Fieldbus segments involved Rosemount 848T multi-point temperature transmitters on the plant, each monitoring eight RTD sensors or thermocouples. Up to 13 of these 848T units can be looped onto a single fieldbus segment, powered by the 3420 Fieldbus Interface Module, allowing a single cable connection to collect data from 104 temperature sensors. Each Foundation Fieldbus segment requires just one cable pair into the control room, with one hazardous area barrier unit. The advantages to BP were significant: to run new multi-core cable over the full 250 m from the control room on an existing plant would have required the erection of scaffolding and a timescale that was unacceptable. By using spare pairs of cables within existing multi-cores, the few cables needed were already in place. BP saved installation costs plus time: eventually, approximately 280 temperature points were monitored on the four reactors, using three fieldbus segments linked to two Rosemount 3420 units to provide redundancy.

Each 3420 Fieldbus Interface Module extracts the individual temperature readings from the transmitters and uses a Modbus connection to transmit the data to the main control system, in this case a TDC3000. This simplifies the data interface to the control system, saving expenditure on extensive I/O additions.

The first project at Hull was to provide detailed monitoring of process temperature gradients during the addition of a process catalyst on part of the ethyl acetate production, where several multi-point sensors are needed to ensure a detailed overview of temperature conditions. Process improvements have resulted, the benefits of which are still being evaluated: the best measure of success is that additional, similar temperature monitoring points and fieldbus segments have been allocated to the vinyl acetate plant, and two further 3420 Fieldbus Interface Modules are to be installed.

cpp 431

Product Data Sheet Rosemount 3420

Rosemount 3420 for Tank Farm Monitoring

Share: