An optimally configured compressed air supply can easily cut energy costs by 50 %. For this reason, rational compressed air generation is increasingly facilitated by electronic speed control. Economical compressed air production, efficient frequency control and effective drying of compressed air in a reduced space: that’s what the SF 24–2 and SF 60–2 to SF 150 compressors have to offer.

Modern electronic controllers have become more powerful by combining both optimised and conventional compressors to ensure the system works in the most energy efficient manner. Each compressor is programmed into these predictive controllers to guarantee that the correct combination is used at all times and provide the required amount of compressed air at the optimum pressure. This intelligent adaptation of volume and pressure optimises the energy requirement, thus reducing the number of stop-starts and cutting electrical costs. Speed controlled drives also make it possible to operate continuously at the right pressure, avoiding unnecessary electrical expense. Frequency controlled compressors come into their own when a system has fluctuating demand patterns, ensuring that peak loads can be handled efficiently.

Infinite speed adjustment

Frequency control allows output control from 25 to 100 % whilst maintaining the exact pressure requirement. The inverter allows infinite speed adjustment of the drive motor, which in turn adjusts the compressor air end to the exact output needed. The frequency converter is designed for soft starts and stops of the drive motor. This means that the current does not exceed its rated capacity during start-up, thus generating additional energy saving advantages.

If the output requirement falls below 25 %, the compressor works uneconomically. It therefore either shuts down or continues to run in idle mode. In view of the need to adapt to the varying air demand, these two reactions must be avoided to enable the compressor to work in the most efficient manner.

Ideally suited

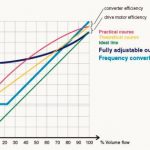

At the same time, if the compressor is expected to work at full load, the absorbed power of the inverter will be between 3 and 5 % higher than that of a fixed-speed compressor also working at full load. It therefore follows that a frequency controlled compressor must operate at optimum efficiency between 25 and 90 % of its rated capacity. Frequency control offers further advantages when it comes to low flow rates, particularly when proportional control of a suction controller is rather inefficient. The two graphs confirm that proportional control provides the greatest benefit between 85 to 100 % flow capacity, whereas at lower values – as mentioned earlier – frequency control is superior in many ways. Overall, frequency control is best suited for use at low flow rates with significant variations in demand. Due to the wide range of inverter adjustment, it is possible – even with air consumption low – to adapt the air delivery to demand and avoid shutting down or running idle.

Frequency controlled compressors can maintain system pressure with 0.1 bar tolerance as opposed to the traditional 0.5 bar tolerances in fixed-speed compressors. In traditional installations with fixed-speed compressors, the cascading system neces-sary to maintain the system pressure means the compressors have to generate at a higher pressure than is actually required in the system. Each additional bar of pressure corresponds to an energy saving of between 6 and 10 %. Utilising a frequency controlled compressor in a multi-compressor system consequently saves energy by generating at optimum pressure. The potential energy savings resulting from the use of frequency control are thus enormous.

Compact modules

The integrated compressor system installed at Boge, comprising a frequency controlled compressor, refrigerant dryer and condensate management system all under one roof, has proved extremely successful. As a direct result, customers adopt a much more flexible approach to installation alternatives. Economical compressed air production, efficient frequency control and effective drying of compressed air in a reduced space: that’s what the SDF 60–2 and SDF 150 compressors have to offer. The SF 60–2, SF 100–2 and SF 150 basic models are equipped with an integrated frequency converter inside the screw compressor switch cabinet. The elimination of a separate exterior switch cabinet not only results in considerably reduced overall space requirements but also offers increased installation flexibility. The compact modules are suited for integration into any compressed air station – for instance as a peak load compressor – and are particularly impressive when it comes to precisely controlling fluctuating compressed air demand. Owing to the intelligent adaptation of the output volume to variations in demand, electricity costs can be reduced very efficiently through partial load operation, the prevention of idle operation and pressure reduction. Due to their continuous volume flow control from 25 to 100 %, the models cover a performance range from 45 to 110 kW with peak pressures of optionally 8, 10 or 13 bar.

The SF/SDF 24–2 can be used for smaller-scale applications. These 18.5 kW screw compressors with integrated frequency control and an optional compressed air refrigeration dryer are available with an 8, 10 or 13 bar pressure range. The frequency converter is integrated into the design in a space-saving manner. Highly efficient ratio control is a standard feature. Important machine operating states are indicated clearly and precisely on the LC display. All models can be easily and successfully integrated into any existing compressed air installation. The effective f.a.d. is 0.44 to 3.05 m³/min.

cpp 402

More information on the products

Online compressed air glossary of terms

Druckluft-Effizient

Share: