Since its foundation in 1947, Emile Egger – the Swiss manufacturer of single-stage centrifugal pumps – has specialised in handling liquids containing solids up to 70 % by weight and gases up to 25 % by volume. Eighteen years ago, Egger added seal-less centrifugal pumps to its manufacturing portfolio. The company recently enhanced its successful cantilever pump and presented the optimised version at Achema 2006 in Frankfurt.

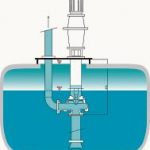

Cantilever pumps based on the SO/SOK design for standard and problematic applications achieve an excellent service life in a variety of industries. The advantages of this design are obvious. Due to the freely moving shaft, no sealing and no shaft bearings are necessary in the liquid area. The pump can therefore run completely dry and operates extremely reliably. Maintenance is reduced to a minimum. As the motor is always mounted above the liquid in a dry area, IEC standard motors can be used. The pump can be installed submerged in the tank or dry-mounted on the side. Another benefit of this pump concept is the Atex classification (Directive 94/9/EC) in categories 2 and 3. The roller bearings are also available in a permanently lubricated version. However, this design has its limitations, as the pump can only be built to certain lengths and cannot meet the gas tightness requirements of Germany’s new air pollution control code.

Improved design

Egger unveiled an improved cantilever pump at Achema 2006. The gas phase in the shaft intermediate pipe is sealed on the bearing side by means of a gas-lubricated double mechanical seal. Liquids which are difficult to seal, or which tend to crystallise or polymerise, can now be handled easily, as can high-temperature liquids or ones that are liable to pollute the environment. Due to the vertical installation, the buffer gas contained in the shaft intermediate pipe prevents all contact between the liquid and the mechanical seal. Only the gases have to be sealed. In wet pit installations, the pit cover is gas-tight and fits inside a manhole.

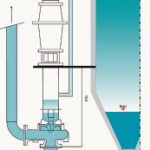

The optimised “dry pit” variant opens up further interesting applications and installation options. It is possible to increase the inlet pressure on the suction side, for example, or to raise the start level above the pit cover level as the bearing housing can no longer be submerged. On a large number of existing sites, standard horizontal pumps can thus be replaced with the Egger centrifugal pump.

Only a few alterations to the pipework are necessary to attain new levels of operating reliability.

cpp 405

More about Cantilever pumps

VDMA-e-Market for pumps

Share: