The Gemü 651 piston operated valve is designed for use in sterile applications and available in open/close or position control versions. The valve and integrated automation module are very easy to install and ready for operation in next to no time thanks to the Speed function.

Thomas Schulz

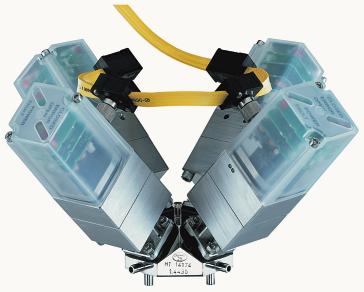

Whereas users previously needed three products to obtain a functional valve, actuator and valve position feedback (which moreover had to be assembled using a valve-specific adapter kit), Gemü now offers a complete and integrated single unit. The name of this new valve type is Gemü 651. Time consuming and costly assembly, tubing and piping are dispensed with by integrating the automation functions into the valve actuator itself. Integrating automation components in a compact valve actuator also improves the cleanability of the valves because the number of critical areas, connections and edges is minimised. Customers additionally benefit from the elimination of many potential problem sources such as leaks or connection and assembly errors.

A remote electrical signal suffices to start the initialisation procedure after a dia-phragm change. The valve travels to the various positions according to a programmed routine and thus detects the new end positions. This process only takes a few minutes and can take place concurrently throughout the entire plant with no need for any manual intervention by service engineers. Complicated manual setting of conventional electrical position indicators working with microswitches or sensors is no longer necessary. And since the housing cover no longer has to be removed, the degree of protection specified and tested at the factory is also complied with.

In combination with a controlling AS-Interface fieldbus system, this represents an ideal solution for automated valves. In addition to simple electrical installation, the valve’s numerous advantages include detailed monitoring and diagnostics options, immunity to interference and easy link-up to other fieldbus systems such as Profibus-DP.

The Gemü 651 piston operated valve is designed for use in sterile applications and available in open/close or position control versions. The valve has normally closed, normally open and double-acting control functions. Due to its compact size, it can be installed in very restricted spaces. All body types in the Gemü modular diaphragm valve system (2/2-way, T, tank wall and tank bottom as well as multi-port valve bodies) are compatible. The valve was developed taking into account the guidelines and recommendations of FDA, EHEDG and GMP. The standard version has M5 control air connectors in the flow direction with optional 90° rotated connectors. The mounting position and flow direction are immaterial. The valve has CIP/SIP cleaning and sterilising capabilities. Coloured LEDs with good visibility indicate the status of the operating voltage, the current function mode and the valve position. The pneumatic actuator housing is made of stainless steel and the automation module housing of PP (polypropylene).

cpp 408

Pumps & Valves 2006

Brau-Beviale 2006

SPS/IPC/Drives 2006

Share: