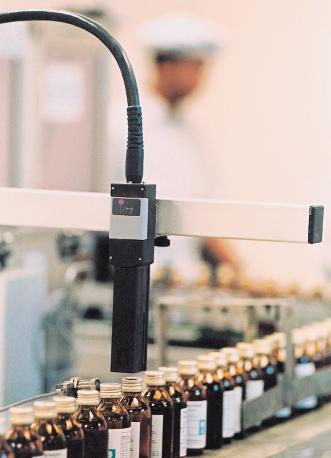

Aventis Pharma is the third largest pharmaceutical company in Bangladesh and the main multinational company in the country. In its Tongi plant Aventis Pharma manufactures drugs that come in all shapes and packaging. To prevent counterfeit, the company is using invisible inks and flexible printers like the S8 Master.

Product information is crucial for traceability and customer information but in Bangladesh it meets another objective: the prevention of counterfeit. Aventis Pharma prints a batch number, the expiry date and the product name on all its products. Depending on the item the message will be printed on the cap of the bottle or on the back of the packaging. This machine marked message is difficult to reproduce for counterfeiters. In Bangladesh, counterfeit is not very widespread so far compared to other Asian countries. However, Aventis Pharma prefers to keep one step ahead of the counterfeiters. “Our imprint is very hard to reproduce unless the counterfeiters acquire the same machine as ours. We also try to have a complicated foil design to make it harder to copy our packaging,” explained Mr. Rahman, director of Industrial Operations. That is why, today Aventis Pharma is showing interest in Imaje´s invisible ink which can be read only under UV light. For this new printing job, the company has purchased nine Imaje S8 Master printers.

The S8 Master is available with one or two printheads with two or four jets. The heads are divided in three different types: the G-head for standard-height characters (1.8 up to 8.5 mm), the M-head for small characters (1.2 up to 5.3 mm) and the P-head for micro-characters (0.7 up to 3.4 mm). Depending on the printhead-types a maximum speed of 5.4, 3.6 or 1.7 m/s can be achieved. Due to its large variety of inks, the S8 Master is also suitable for special marking on glass and synthetic materials as well as for processing non-migrating, food-safe or invisible inks. Up to four lines per jet can be printed with the S8 Master and not only text but also logos and barcodes. The printer has got a stainless steel cabinet and a sealed keybord which is resistant to solvents. The patented cleaning system automatically rinses printheads to ensure a trouble-free startup and optimum operation. The ink circuit of the S8 Master is based on a Peltier condensor with an integrated solvent vapor recovery system that can reduce solvent consumption up to 30 %. Besides the automatic ink pressure adjustment, the S8 Master also ensures a continuous automatic regulation of the ink viscosity and ink temperature.

cpp 451

Share: