Ploughshare mixers and vacuum shovel dryers are proven systems used in the pharmaceutical industry. These machines are successfully employed for mixing, granulating and drying high-quality pharmaceutical products. The array of specialised applications is very broad, as this overview shows.

The highest standards of quality and safety are prerequisites in pharmaceutical production. Lödige offers customised pharmaceutical machines which comply with all current GMP design requirements and FDA guidelines. The company also has a pilot plant with a separate area specifically dedicated to pharmaceutical trials and small batch sizes for process development projects or reliable scale-ups under production conditions. Amongst other things, the pilot plant is equipped with ploughshare mixers and vacuum shovel dryers.

The advantages of horizontal ploughshare mixers lie in the short mixing time – usually between two and three minutes – and the very high mixing precision in the region of 1 : 100,000 or more for many products. This is enabled by a fluid bed, which is mechanically produced by the mixing elements. By using a constant Froude number, which is an indicator of product movement in the machine, test results or validated processes can be reliably transferred between various mixer sizes. By virtue of their horizontal design, ploughshare mixers require less drive power and a smaller overall height than conventional, vertical high-shear mixers.

Mixing and granulating

Besides mixing, the ploughshare mixer is also suitable for granulation processes. A granulation agent can be introduced into the fluid bed using several different methods. The interaction of the product particles, mixing elements and mixing drum, together with the resulting shear forces, causes granules to form. The results achieved in this way are absolutely comparable with those for high-shear mixers. The desired granule size can be set with the aid of one or more rapidly rotating choppers and any lumps broken up. Discharge through an integral sieve mill for final size calibration of the moist granules rounds off the processing options. The classic applications for ploughshare mixers in the pharmaceutical industry include premix manufacturing and lubricant addition. In a conventional tablet manufacturing process, the granules are mixed with a lubricant (usually magnesium stearate) prior to compression in the tablet press. A ploughshare system can be chosen here as an alternative to the popular container blender. Several upstream process stages (e. g. premixing or granulation) can also take place in the same machine. Moreover, ploughshare mixers can be employed for wet granulation of the tablet masses and take up less space than vertical high-shear mixers. Direct discharge is possible into a fluid bed dryer through a sieve mill.

Advantages combined

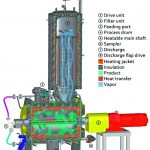

Vacuum drying is characterised by low drying temperatures and high evaporation rates which are gentle on the product and lead to shorter processing times. Vacuum drying in a horizontal shovel dryer unites the advantages of the drying process with the processing potential of a horizontal ploughshare mixer. Apart from manufacturing mixtures with a high level of precision, the mixing tools make a crucial contribution to the drying process by ensuring a constant exchange between the heating surface and the moist product, thus enabling effective heat transfer.

Compared to vertical drying systems, the horizontal dryer has a larger heat exchange surface, which is conducive to shorter drying times. In addition, the system has various options for liquid addition and distribution, and is thus equally suited for granulation processes. The ability to fill or discharge through an integrated sieve mill in order to pretreat the material or for size calibration of the granules rounds off the system’s processing capabilities.

Dryer applications

There are a multitude of applications and processes in the pharmaceutical industry that can be carried out in vacuum shovel dryers, only a few of which are outlined below:

- Drying of active ingredients: As a result of previous processing steps, APIs often have a relatively high moisture content that must be significantly reduced before they can be converted into a final product. The vacuum shovel dryer is ideally suited to this task due to its high evaporation rates as well as the option of low-temperature drying for temperature-sensitive active ingredients (e. g. hormones, plant extracts, vitamins, etc.). The API drying process often includes the evaporation of solvents, which can lead to the formation of an explosive atmosphere in the dryer. This is easily handled, however, due to the vacuum atmosphere in the machine.

- Containment/single pot applications: Since several process stages can be combined in a closed system, the vacuum shovel dryer is perfect for solid dosage forms with toxic or highly potent active ingredients. The dryer is fed with pre-weighed components and the mixing, granulation, drying and sieving steps (with a sieve mill at the machine discharge) can be carried out consecutively, with no need to transfer the product or provide further machines. The operator is protected by containment flaps during product feeding into and discharge from the system.

- Manufacture of effervescent granules and tablets: After preparing a pre-mixture with subsequent granulation, a chemical reaction is initiated but interrupted after a short time due to the sudden evaporation of the water contained in the product. The vacuum shovel dryer has become established here as a very efficient system because rapid evaporation can be easily achieved by generating a high vacuum in addition to mixing and granulation. When the dry granules are discharged from the machine, they can additionally be size-adjusted by a sieve mill.

Hall 6, Booth B78

www.cpp-net.com search: cpp0217lödige

Dominik Sander

Sales Representative Life Science Technology, Gebr. Lödige Maschinenbau

Share: