Peristaltic tube pumps are positive displacement pumps: at Spetec they are comprised of a roller head driven directly by a wear-resistant stepper motor and an arrangement for securing the tubing. These pumps are not produced off the shelf but are manufactured individually for each customer. As miniature models, they are frequently used for instrumental analysis in the chemical industries.

Peristaltic pumps operate by constantly compressing and releasing tubing. The tubing is pressed into holders around a rotating roller head by pressure arms. The liquid is thus conveyed along the occlusion point of the tubing by an alternating surface of the roller head caused by the rollers and their movement.

The first tube pumps were initially employed to pump blood back in the 1960s. They soon found their way into industrial applications, as self-priming pumps of this kind are very easy to use and are also suitable for abrasive or viscous media. In common with all tube pumps, designs with a pump head – initially often with just two rollers – exhibit considerable pulsation.

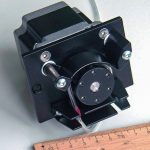

If the application requires a constant flow, it is necessary to increase the number of rollers to eliminate pulsating interruptions. Another essential aspect for achieving this characteristic is a suitable tubing material which retains its elasticity for as long as possible and is resistant to different liquids. Tube pumps from Spetec therefore are designed with anything from 6 to 16 pressure rollers. The pictures (Fig. 1: Peristaltic pump with 6 rollers, Fig. 2: Peristaltic pump with 12 rollers) show two types with different numbers of rollers as OEM versions. One special feature is that they are custom-manufactured in terms of performance, size and colour. As all the component parts are produced in-house, it is also possible to meet special requirements. The Spetec philosophy is to provide pumps that not only offer excellent technical properties such as very low pulsation, high precision and a stable flow rate, but which also have an attractive, distinctive appearance. There are no traditional production models. Instead, only some of the basic components – such as the roller head, tube holders and pressure arms – are reused. The visual appearance can always be adapted to customer requirements, however. For instance, the colour and shape of the base plate on which the pump itself is mounted can be custom-built, as can various other components. This results in a personalised product that carries the manufacturer’s signature. Smaller pumps have also been designed to take account of the trend towards more compact analysis equipment. Figure 3 shows an example.

The Perimax is a stand-alone version of the tube pump. This pump contains 12 or 16 rollers per pump head and can be supplied with up to 6 channels. The Perimax 12 delivers a flow rate of up to 20 ml/min. The Perimax 16 achieves double this figure by splitting and phase-shifting the 16 rollers, thus allowing the use of dual tubing. Phase-shifting moreover leads to virtually pulsation-free delivery.

Suited for instrumental analysis

Peristaltic pumps are frequently used in instrumental analysis, ICP spectrometry and atomic absorption spectroscopy (AAS). Among the other fields of application are medical engineering, pharmaceuticals and foodstuffs.

Extensive automation of the processes in chemical analysis labs requires the use of pumps which are capable of delivering a constant flow of sample solutions, for instance in systems for water and environmental analyses. The semi-automated processes in ion chromatography likewise demand the use of high-precision tube pumps.

Most emission spectrometers for direct solution analysis, such as those based on ICP excitation, nowadays contain this kind of tube pump. It is particularly important with plasma flames that there is virtually no pulsation, as the plasma tends to induce pulsating movements.

Wide range of tubing materials

Another advantage of tube pumps is their ability to pump slurried and higher-viscosity fluids. To do this, suitable pump tubing is needed. Spetec has been manufacturing tubing in-house for many years and offers a wide range of tubing materials. Depending on the medium being pumped, the tubing can be manufactured from different materials and recommended for different applications:

- PVC: suitable for medical products, ETO sterilisation, meets USP Class VI

- Polyurethane (ATB Medical Grade): suitable for medical products, gamma sterilisation possible, meets USP Class VI

- Solvent Flex (solvent-resistant): suitable for petrol, oils, RoHS and Reach compliant

- Santoprene: for non-fatty foodstuffs, meets NFU Standard 51 (not suitable for medical products)

- Silicone (MF 160U): for technical products as per ISO 10993

- Fluorinated rubber (comparable with Viton): high thermostability, RoHS and Reach compliant

All tubing is available in a variety of configurations. On request, bridges can be fitted at different intervals to suit the application scenario. The inside diameters of the tubing range from 0.12 to 3.2 mm.

Metering tiny volumes

The metering capacity of tube pumps is restricted to the millilitre range. Some manufacturers therefore offer syringe pumps that are employed for microfluidic methods in analysis labs, for instance. Spetec, too, has developed a syringe pump with special characteristics. The use of a stepper motor drive made it possible to achieve the high resolution of 25,600 steps per revolution. This permits metering volumes down to a few microlitres or nanolitres, which is particularly important for research in medical and analysis labs.

Direct displacement and the high step resolution allow the medium volume to be maintained with ±1 % precision. The flow rate accuracy remains at a constant high level, so that syringe pumps are also unmatched when it comes to metering tiny volumes: no better technology exists at present. As with tube pumps, the medium does not come into contact with any of the mechanical parts. The syringe is easily replaced and it is possible to switch between different solutions quickly. Unlike tube pumps, syringes can pump in both directions, i.e. infusion or withdrawal.

www.cpp-net.com search: cpp0217spetec

Prof. Knut Ohls

Scientific consultant,

Spetec

Share: